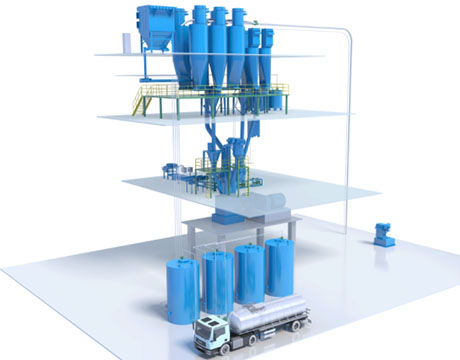

The upper auxiliary machine and microcomputer control system of intelligent environment-friendly internal mixer can meet the whole process of closed automatic transportation, storage, weighing, batching and feeding of various raw materials (carbon black, powder, liquid and rubber) in the internal mixing production process of rubber and plastics, and implement microcomputer intelligent control in the whole process of processing and production process.

Rubber Products Production Line with Kneader mixer

The upper auxiliary machine and microcomputer control system of intelligent environment-friendly internal mixer can meet the whole process of closed automatic transportation, storage, weighing, batching and feeding of various raw materials (carbon black, powder, liquid and rubber) in the internal mixing production process of rubber and plastics, and implement microcomputer intelligent control in the whole process of processing and production process.

Main components

1. Storage, weighing and feeding of carbon black and powder;

2. Liquid delivery, storage, weighing and injection;

3. Rubber conveying, weighing and feeding;

4. Automatic control system (rubber mixing information management system).

Main Technical Parameters:

| Powder scale weighing range | ≤200 Kgs |

| Oil scale weighing range | 1-50 Kgs |

| Powder weighing accuracy | Static≤±0.1% F.S, dynamic:±0.1--±0.5Kg. |

| Oil weighing accuracy | Static≤±0.1% F.S, dynamic:±0.1--±0.5Kg. |

| Conveying capacity | 1-1500Kg/h |

| Transmission distance | Horizon≤80m; Vertical≤20m |

| Pipe diameter | DN50-100 |

| Air source | Root's Blower |

Features:

Δ This system is suitable for banbury capacity from 55L to 160L

Δ It is applicable for the factory building structured of 1-storyey or 2-storey, saving the construction cost for new factory building

Δ This system is to fulfill the storage, conveyance, weighing and dosing of the major ingredients, such as carbon black, white fillers, and oils

Δ The storage area are separated from the production area

Δ This system had integrated mixer upstream equipment, banbury, rubber scale in one program, and realize the online control

Δ This system is realized the production automation and management information systemization

Δ This system mainly applicable for production of rubber products, plastic products, shoes, rubber cable materials, chemical materials…

Δ This system had combined vacuum type conveying and screw type weighing, less space occupancy (1-2 meters higher than full vacuum system) and high weighing accuracy(+/- 50g-0.5%).