ChiYu Co., Ltd. is a professional supplier of Mixer, Powder Mixer and U Type horizontal ribbon blender.it is suitable for 3-in-1 coffee powder,milk powder, flour, seasoning powder, food additives, milk tea powder, cocoa powder, chinese herbs, western medicine, grains powder, ice cream powder and chemical mixing.

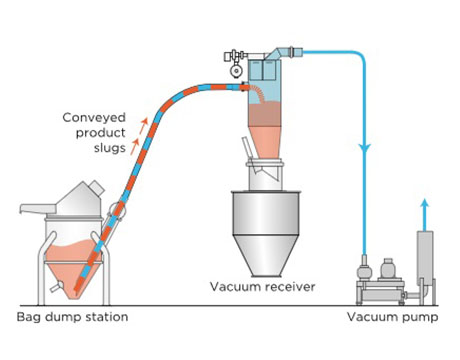

ChiYu Co., Ltd. is a professional supplier of Mixer, Powder Mixer and U Type horizontal ribbon blender.it is suitable for 3-in-1 coffee powder,milk powder, flour, seasoning powder, food additives, milk tea powder, cocoa powder, chinese herbs, western medicine, grains powder, ice cream powder and chemical mixing.Granules or powder are sucked directly from container into mixing machine through conveyor pipe by vacuum conveying system.the free powder are collected by sanitary grade dust collection device.it is a device with dust-free, effort-saving, manpower-saving and non-contamination.

Working Principle:

A, The horizontal axes make the materials move up and down.

B, The outer ribbon gathering the material from sides to center and the inner ribbon pushing the material from center to sides.

C, Every screw makes the materials do axial and radial movement, the materials do relative cyclical movement so to gain the intensive mixings ends.

Characteristic:

A, Fast mixing speed can satisfy the rigorous demand of mixing the materials with different physical property.

B, The rotation is under critical speed, which will reduce the effect of fragmentation to the material(e. G. Crystal particle)

C, Lower height of the container is convenient for installation.

D, The positive and negative ribbons are set up at he same level, forming a mixing environment of low power but high efficiency.

Advantage:

(1) Large loading factor and small equipment area.

(2) With the shear blade inside, the micro mixing can be achieved.

(3) According to the production demand, the equipment can be used as a large-scale machine, and the price is cheaper than other mixers.

Note: mixer selection is a very important step, your detailed material information, processing and factory arrangement are very helpful to get professional technical support from us.

Technical data:

| Type | Total Volume(M³) | loads coefficient | Motor power KW | Size(L×W×H) | Net weight(kg) |

| LT-0.1 | 0.1 | 0.4-0.8 | 3 | 1190×740×770 | 330 |

| LT-0.3 | 0.3 | 0.4-0.8 | 4 | 2030×630×980 | 720 |

| LT-0.5 | 0.5 | 0.4-0.8 | 7.5 | 2320×730×1130 | 980 |

| LT-1 | 1 | 0.4-0.8 | 11 | 2800×920×1320 | 1700 |

| LT-1.5 | 1.5 | 0.4-0.8 | 11 | 2800×920×1320 | 1800 |

| LT-2 | 2 | 0.4-0.8 | 15 | 3180×1020×1550 | 2100 |

| LT-3 | 3 | 0.4-0.8 | 18.5 | 3310×1120×1640 | 3000 |

| LT-4 | 4 | 0.4-0.8 | 22 | 3750×1290×1820 | 3980 |

| LT-5 | 5 | 0.4-0.8 | 22 | 4220×1400×1990 | 4620 |

| LT-6 | 6 | 0.4-0.8 | 30 | 4220×1500×2100 | 6180 |

| LT-8 | 8 | 0.4-0.8 | 37 | 4700×1610×2260 | 8200 |

| LT-10 | 10 | 0.4-0.8 | 45 | 5520×2960×2720 | 9520 |

| LT-12 | 12 | 0.4-0.8 | 45 | 5720×3010×2840 | 9950 |

If you want to get detailed information about the horizontal ribbon mixer price, you can click here to contact us!