Copyright © 2021 Zhangjiagang ChiYu Automation Equipment Co., Ltd. by iwonder.cn All rights reserved. Site Map

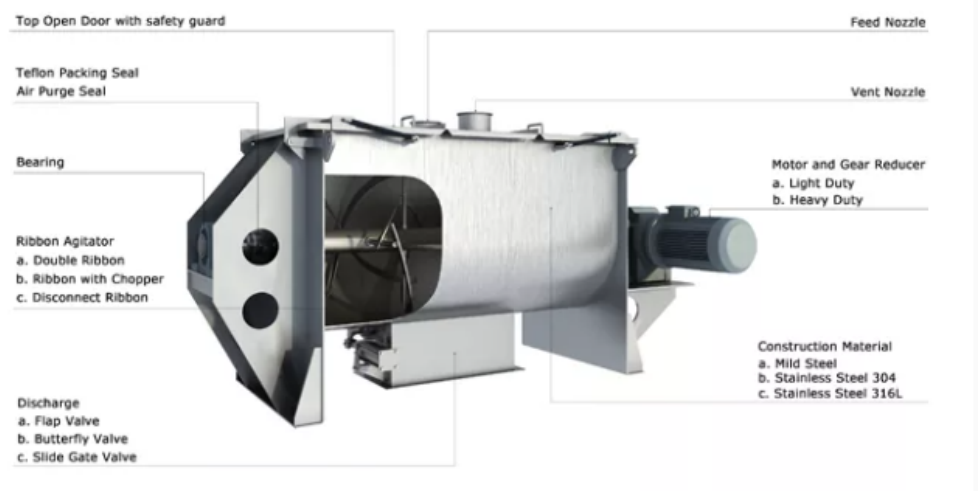

Ribbon Blender (also named ribbon mixer) is a basic industrial mixing machine. They consist, basically, of a trough-shaped shell (usually 2 to 3 times longer than it is wide) with a semicircular bottom, fitted with a horizontal longitudinal shaft on which are mounted arms supporting a combination of ribbon blades, paddles or helical screws set at a fairly close clearance to the semicircular mixer body so that no layer of material remains on the bottom of the ribbon mixer. The most effective design of ribbon layout is the double spiral in which the outer ribbon moves the product in one direction and the inner ribbon moves it in the opposite direction.

The ribbons rotate and move materials both radially and laterally to insure thorough blends in short cycle times. Ribbon agitators are used for blends that will be between 40 and 70% of the rated capacity of ribbon blender.

Mild mixing which will not break the physical size of material

More loading factor: ribbon blender’s working volume is between 40%-70% of the total nominal volume, but generally speaking, 60% is the maximum loading ratio of ribbon blender when mixing heavy bulk-density material

Easy Cleaning: usually, the opening at the top cover is very large to touch into the inner surface for cleaning purposes.

Easy Maintenance: the structure is very simple, easy to dismantle and maintenance

Low Power Energy

ChiYu corporation has been a powder mixer manufacturer since 2013, decades years experience and constantly improving technology make vortex ribbon blender stand out with below special features

1. Vacuum/Pressure

2. Heating/Cooling Jacket

3. Spraying Nozzle for liquid

4. Heavy-duty drive unit

5. Various Outlet Valve depends on the customer

6. Process requirement

7. Explosion-proof for electricity

8. Electrical Control Panel system

9. Teflon Coating for material contact part

10. Other Special Customize Design

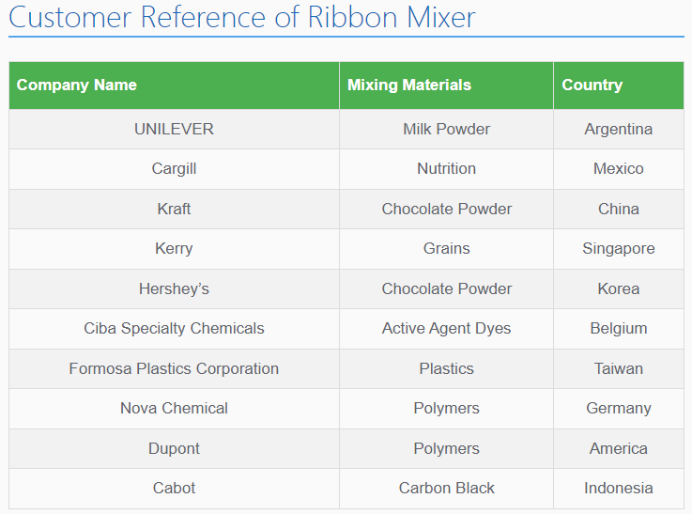

The ribbon blender’s versatility for blending solids combined with its ability to perform heating, cooling, coating, and other processes make it a very popular mixer.

Zhangjiagang Chiyu Automation Equipment Co., Ltd focus on building bulk solid handling plant and supplying related machines and fabricated parts to the plastic, chemical and petrochemical industry.

Our long suits are the best understanding of bulk material properties and the handling process. We are good at solving problems which exist in bulk solid conveying, storage, weighing, mixing and screening.

For any more information about ribbon blenders, please do not hesitate to contact us.