Copyright © 2021 Zhangjiagang ChiYu Automation Equipment Co., Ltd. by iwonder.cn All rights reserved. Site Map

The manual operation of mixing and dosing batch materials gradually reduced as the automatic dosing and mixing system came into operation. Technological advancements have, on a general basis, impacted the market size and productivity, as more consumers can get their products early enough because of the speed involved in production.

Unlike the traditional method of mixing, the dosing and mixing system is used for factories that require more product output within a short period.

In plastic industries, they make the dosing and mixing of plastic raw materials easy and ensure that the output is conveyed to the appropriate channel.

Are you wondering what the dosing and mixing system is all about? This article will give a clear insight into all you need to know about the dosing and mixing system and the benefits you stand to gain when you implement its usage for your operations.

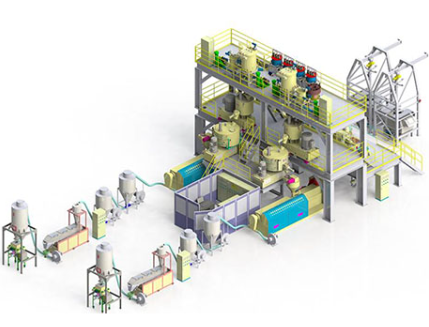

The dosing and mixing system is a two-in-one system that allows both dosing and mixing operations. It constitutes the automatic dosing mixing system and conveying system, among others.

It effectively functions in the areas of weighing raw materials, input, mixing, and conveying the plastic output to the plastic extruder.

The automatic dosing and mixing system finds its application in the manufacture of plastic PVC pipes, SPC floors, and PVC wall panels among others.

The automatic dosing and mixing system makes it easy to change recipes. It gives an accurate measurement of recipes used for a particular production and at the same time allows uniform mixing.

It also allows the diversity of raw material input to obtain other distinct products.

If you need to make sure your workshop or work area remains clean, then you should consider going for the automatic dosing and mixing system.

This is because the points of input and output are large enough to allow more input and output of materials at once. In addition, it is easy to disassemble the dosing and mixing system into smaller units so that it can be easy to clean.

A machine is used to increase the efficiency of production and the speed with which the output is recovered. No one likes a situation whereby a machine is much slower than manual labor.

The dosing and mixing system constitutes high efficient and high-speed machines that can be used to enhance the output of production.

The dosing and mixing system has helped many industries, especially the plastic industries to meet up with demands of the market. This is possible because of the efficiency and speed affected by making use of these machines.

Do you want to purchase your dosing and mixing system now? We are dedicated to providing the best quality products to our customers.

Kindly contact us for your high-speed and highly efficient automatic dosing and mixing systems.