Suitable for continuous conveying of powder, pellets and small lump materials in a closed tube loop. Horizontal, vertical inclination or its combination layout is possible. Typical application includes those dusty bulk solids conveying in plastic, rubber, chemical and food industries.

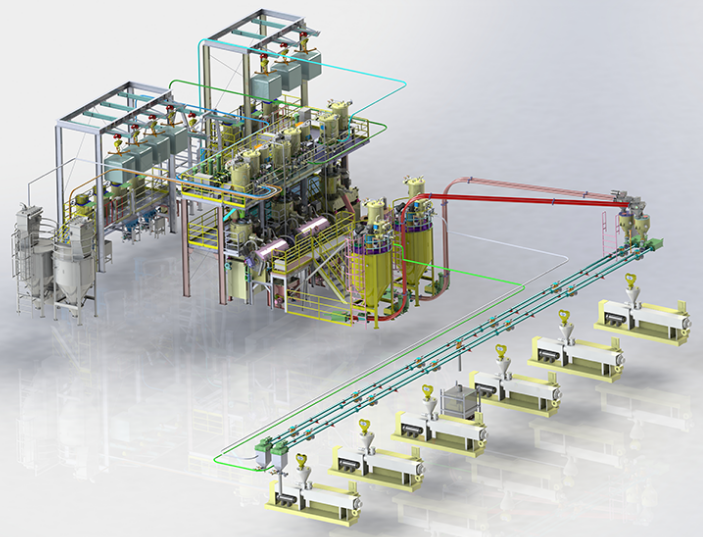

Tube Chain Auto Feeding Conveying System For PVC Extruder With Dosing Equipment

Application and introduction

Tube chain conveyor is the continuous mechanical conveying equipment for fine powder, granule and massive materials.

It is a good choice for below applications:

Industry of Fine Chemicals: dye, paints, coating, carbon black, titanium pigment, ferric oxide, ceramics powder, coarse whiting, fine particle calcium carbonate, bentonite, molecular sieve, kaolin, silica flower, active carbon and so on.

Pesticide Ore: urea, ammonium chloride, ammonium bicarbonate, soda powder, solid pesticide, tungsten powder, fish oil, copper fine ore powder, coal powder, rock phosphate, alumina powder and so on

Building Material: cement, clay, yellow sand, quartz sand, clay powder, silica, limestone flour, dolomite fines, Wood chips, fiberglass, silicon dioxide, French chalk and so on.

Foodstuff Industry: flour, starch, grain, milk powder, food additive

1. Positive-displacement conveying device can realize conveying and computing powder, easy centralized control, increasing degree of automation and satisfying requirements against environmental protection of modern enterprises.

2. Compact conformation, little space usage, tridimensional conveying direction.

3. Flanges between inlet and outlet are airtight, then there is no need to install filter. When conveying powder, it can be feed in air and can assure that there is no dust spread into environment.

4. Powder is conveyed smoothly along the lines almost with none inside movement; therefore, there is little dilapidation against materials, slow curve conveying make little material granule into scraps.

5. According to different feeding conditions, distance between inlets can exceed 10m.

6. Chain wheel has been under hardening with minimum abrasion

7. Special transfer dish with extremely low coefficient friction and stable delivery capacity.

8. all our tube chain conveyors use our own computer program for different parts such as conveying line and curve parts to maintain necessary static friction and pullup and providing precise data to reach to low noise and little abrasion.

9. three dimension to convey: horizontal, inclining and vertical mix.

Client Name: Sundiwpc Plastic Co,. Ltd.

Plant Location: Nanjing, China

Construction Year: 2016

Final product: PVC pipe

Plant for: Automatic feeding system.Pneumatic conveying system, Dosing and weighing