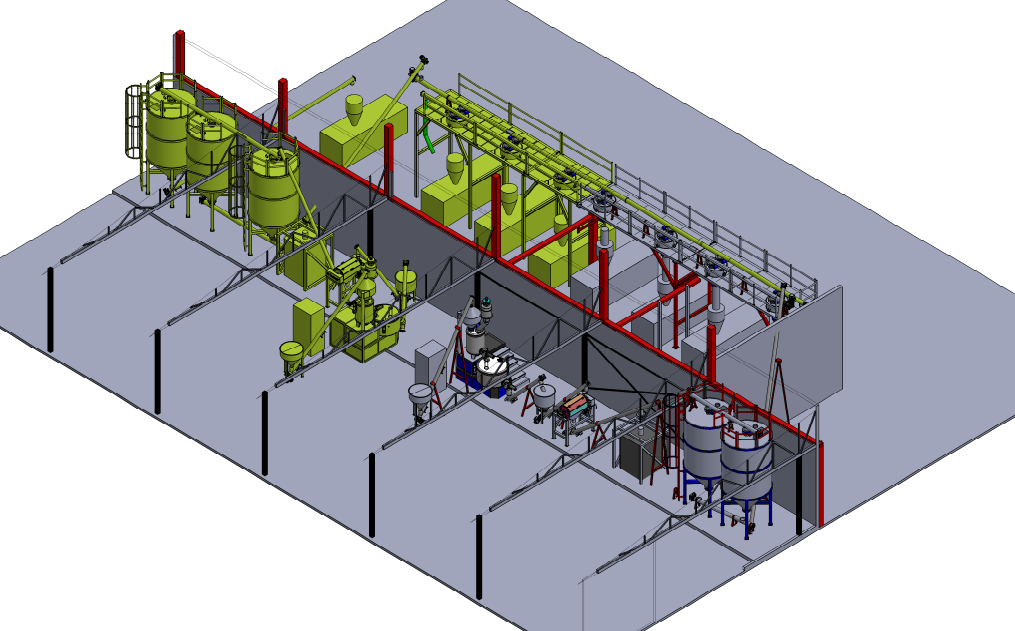

This system includes automatic feeding system, mixing system, vacuum conveying system, etc. it is suitable for automatic weighing, mixing and conveying of all powder and particle materials to plastic extruder or injection molding machine.

Automatic Feeding Screw Conveyor For Powder With Pneumatic Vacuum Conveying System

Application and introduction

Screw feeder is designed for bulk solids conveying or dosing of powder or pellets into batch weighing station.

Features:

1. Gear motor driven by frequency inverter.

2. Screw with different pitch suitable for bad flowing bulk materials.

3. All parts in contact with products are in stainless steel 304.

The system is designed for the automatic feeding of multiple extruders. The storage and transportation of materials are carried out in closed stainless steel containers and pipes. Some dust removal measures are taken to effectively prevent dust pollution and keep the workshop clean. The control system is controlled by imported PLC, and the main electrical components are imported famous brand products to ensure the long-term, reliable and efficient operation of the whole system. The control system can automatically or semi automatically complete the whole feeding process. The simulation screen can display the operation status of each part of the system in real time through the indicator light, and can flash the alarm for the failure part to attract the attention of the operator. The extruder adopts the combination of vacuum feeding and screw feeding. The silo is equipped with two level meters. When the lower level meter shows that there is a lack of material, the feeder will work automatically to fill the material in the large silo to the small silo. When the upper level meter shows that the material is full, the feeder will stop working and temporarily stop feeding. In order to ensure the normal and continuous operation of the extruder, a 50L small hopper is added above the extruder and a level gauge is equipped respectively. If any one of the six level gauges shows a lack of material, the screw feeder will automatically start to work and start feeding until all the six level gauges light up to show that the material is full, and the screw feeder will stop working; if one level gauge is short of material, the screw feeder will start working again, The whole feeding process runs automatically under the control of PLC.

Automatic PVC compounding system is usually composed of the following subsystems: material collection system, material conveying system, metering batching system, mixing unit, material storage equipment, feeding system, dust removal system: central control system, central monitoring system ,etc.The composition and principles of the subsystems are described as below:

1. Automatic PVC Mixing Centralized Feeding System Material collection system

The conveying of the materials is the key to the automation of the compounding and feeding system. In the PVC automatic compounding system, the conveying system occupies a large proportion:Including the conveying from the bagging station to the transition silo upon the batching scales,the finished materials conveying from the mixer to the finished silo ,and also the finished materials conveying from the finished silo to the extruder.

2.Automatic PVC Mixing Centralized Feeding System Material storage equipment

Material storage equipment are separately silos mainly used for storing raw materials and finished materials.

PVC raw material storage silo has 150m3 of effective volume.The material touching storage materials are all stainless steel,and polished . The outside surface is done with pickling passivation treatment.Consist with silos,dust removal equipment upon the silos ,steel ladder,fences,decompression cap,gate,and other components etc.

Can automatically control the materials incoming and outgoing by setting the level gauge, it has nice appearance,strong structure,wind proof and other features.In order to ensure the qualified rate of the finished tubes, it is necessary to consider the surplus volume of the finished material’s silos, normally not less than 12 hours, and also the finished material silos’ design adopts the homogenized structure to ensure that the materials are not separated from the stratification.

3.Automatic PVC Mixing Centralized Feeding System Feeding system for extruder

Feeding system is composed of vacuum feeder or screw feeder.

Vacuum feeder composed of the feeding funnel, suction gun,vortex fan, pulse filter,butterfly valve and storage silos. The biggest rated feeding capacity is more than 1500kg / h.

Screw feeder is a rodless screw conveyor,can be bend in a certain degree, suitable for the feeding for the extruder.