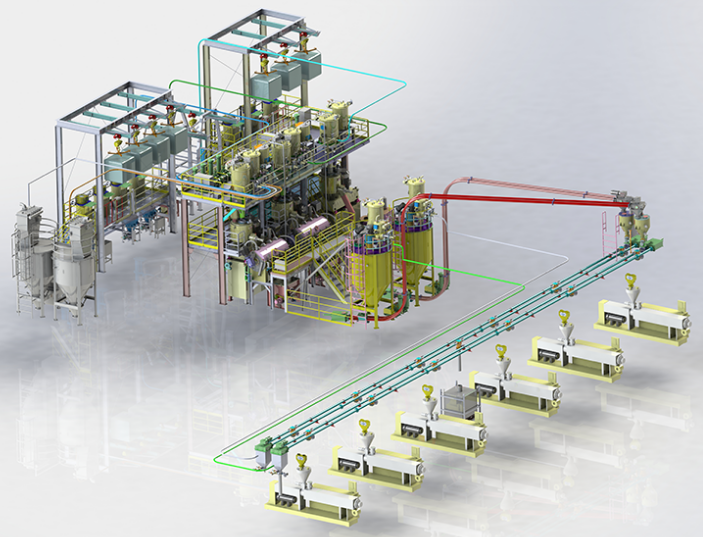

This system includes automatic feeding system, mixing system, vacuum conveying system, etc. it is suitable for automatic weighing, mixing and conveying of all powder and particle materials to plastic extruder or injection molding machine.

Automatic Feeding Dosing Mixing Conveying System For SPC/LVT Floor Extrusion Line

Application and introduction

SPC PVC Automatic Mixing Solution System/Automatic PVC Mixing Centralized Feeding System Feeding system for extruder

1. The system use computer control system of industrial PC combined with PLC for real-time dynamic monitoring, stores a plurality of groups of formula.

2. America Toledo bellows type metering sensor and control meter can can ensure the system’s dynamic stability and accurate measurement, the dynamic accuracy is plus or minus 3 per thousand.So the system also can reduce labor costs.

3. Air bag type unique unloading device used, for you to eliminate viscous material ”bridging” trouble.

4. The system pressure balance type centralized dedusting system, so that each dust reduced to low leak point.

5. The automatic material dosing feeding mixing system is fully enclosed conveying design, it can prevent secondary pollution and dust hazards.

6. A variety of system combination model, to adapt to various plant conditions.It is suitable for plastics,rubber,chemical and food industry, such as PVC LVT vinyl flooring production line.

Solutions:Effectively prevent dust dangers and risks

Safe and comfortable working environment is our consistent pursuit both from enterprise and employee’s perspective.The most directly way to eliminate dust dangers is to reduce dust or dust spread.

As to resolve it, we need only a reliable system,which could eliminate and dispel dust.The following equipment and system is used by most PVC or wood manufacturers in production process.

In order to salve these problems, our company design a SPC PVC automatic mixing solution system which the computer can automatic control weigh and batching, and feeding to extruder. This batching solution consist of automatic weighing, after weighing put the material in to the mixer unit, than use the air-operation pipeline transport the mixed material to extruder.

The advantage of SPC PVC Automatic Mixing Solution System:

1.Automatic feeding system –unmanned

SPC PVC automatic mixing solution is professionally designed for PVC or WPC plastic industry in mixing workplace. This set of confined system is used for automatically measuring, feeding, mixing, dosing to the extrusion of variety powders,particles and liquids. It leads to labor-saving,and prevent from directly touching with powder.

2.Central dust collecting system–dust-free

The mixing workplace of PVC and WPC plastic industry is mass dust and workers are mobile.In the use of centralized feeding system,we choose to connect the dust collection with the dust occurring outlet,so that collecting and recycling use of this part. Dust-free workshop is not only the modern industrial standard but also can save a lot of material and labor.

3.The central control system—intelligentize

Intelligent control system is to avoid mistakes and loss caused by manual operation, such as the wrong formula of feeding raw material lead to batches unqualified products and wast of secondary processing. The lack of automatic dosing function would result in short filling,which is the damage to screw and extruder.The key point is that lack of an automatic system to calculate materials based on production.

According to the material wast in enterprise each year, the amount of labor costs and other invisible costs is often higher than the investing amount of a certain small devices.