Copyright © 2021 Zhangjiagang ChiYu Automation Equipment Co., Ltd. by iwonder.cn All rights reserved. Site Map

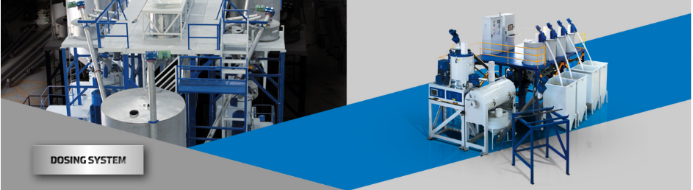

We are one of the major leading manufacturers of PVC Mixer machines, PVC Dosing systems, Feeding systems and Auxiliary equipment for PVC sector since 2004. ChiYu Company has gained an outstanding reputation in many countries by considering customers' demands since its establishment, evidence of this is that we have excellent references from many companies all around the world. Additionally, we produce equipment and accessories with PVC mixer machines for a variety of companies that uses PVC Materials.

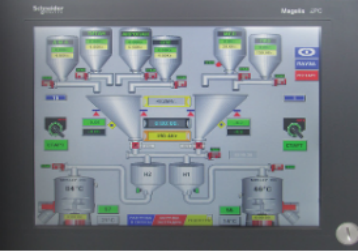

Chiyu Automation company offers dosing systems of raw materials, compatible and ideal automation processes for production lines and different capacities according to its customer's budgets and needs. Dosing systems weigh the PVC formulation automatically in a desirable ratio by load cells very precisely and transferring them into feeding silos. The automation process of this system could be watched and controlled through a PLC control monitor. The ratio of PVC formulation which is used in production could be changed and rearranged by the buttons on the operator panel.

1. Maximum capacity and efficiency

2. Saving time

3. Save handwork

4. Additives used in each product provide the same rate and ensure the continuity of product quality.

5. Reduce waste

We are offering dosing systems of the raw materials, compatible and ideal automation processes for production lines and different capacities according to its customer's budgets and needs.

|

|

|

|

Big Bag weighing unit helps producers to accelerate the production process, at this system PVC or Calcite powder fills into the weighing unit with using of screw conveyors and load cell device weighs the required dosing portions. After weighing, screw conveyor will load required portion into the mixer machine for mixing with another additive.

The plastic production industry has to provide enough raw material storing for constant production processes. There are two ways of storing in the market; first one is using 25 kg bags, this way is suitable for low production capacity companies and easy for carrying with human power. The second one is suitable for high production capacity with bags of 500 kg, 1000 kg and highest capacity big bags, but they are not easy to carry by human power, to handle them it helps big bag discharge station for emptying these units at the production.

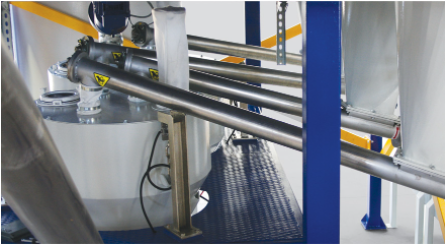

Screw conveyors are widely used for conveying or movement of raw materials from one place to another. These conveyors are specially used for dusty, hot material and they are fabricated from quality materials like stainless steel to resist corrosion, and other metals for purpose of vertical or horizontal transportation , according to the size and capacity Screw conveyors are available in a variety of types.

Advantages

Maximum capacity and productivity – Save time – Save handwork

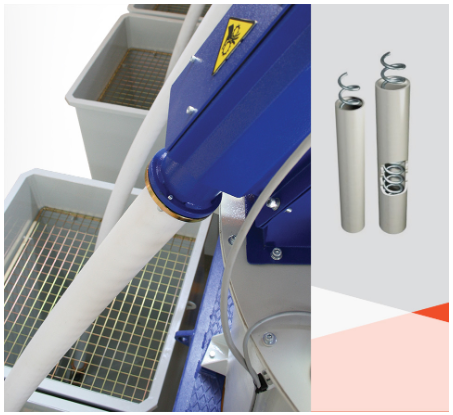

The flexible spiral conveyers, provide an economical means to convey powder or granular material. These conveyors use a stainless steel spiral or steel, enclosed within plastic tubing and they are suitable for transferring material from feed hopper to discharge point. According to the size and capacity Screw conveyors are available in a variety of types.

Advantages

Easy to clean – Dust free – Economic

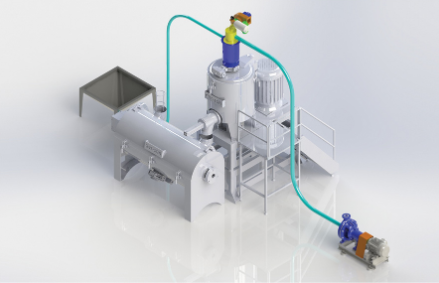

Plastic powder and granules can be transfered gently with pneumatic conveying systems. Pneumatic conveying, handling and dosing systems are used to convey, load, unload, fill, discharge and dose bulk solids. Granules and powder materials can be transported through pipes by vacuum or pressure. There exists large number of applications that use pneumatic conveying systems.

In production for providing the desired process in the purpose of storing and holding capacity from 5 to 30 m3 volume of the raw materials storage silos are operative. Raw material storage silos can be manufactured from black metal and stainless steel, assembly and design by our factory. Dimensions and diameters of the silos are designed and produce according to the capacity of the production (client factory) and size of the area to be established. In production of materials with intensive calcite to provide easier drain vibro-motor of adequate power is used.

Liquid dosing systems generally include the dosing of different liquids (as Dop,paraffins ,soya oil etc. ) for heater mixer according to the prescription. Liquid materials are stored in tanks of the system weighed Gravimetrically and pumped to desired heater mixer by means of pumps and controllable valves through pipelines.To keep a stable temperature liquids are preheated in the holding tank.Gravimetric dosing is based on sensitive load cells that weigh the material precisely. The tolerance is very low %0.1 . All the system is controlled through a PLC sophisticated software via the operator panel.

Advantages

• Material save

• Handwork save

• Maximum capacity and productivity

Hoppers are used primarily for handling raw materials and products as storage vessels as well as transporters, and feeders for different stages of the processes. Types of hopper, conical produced from stainless steel or steel with anti corrosion paint and come in a variety of sizes depending of the requirement.

Automatic feeding systems of the product find themselves application areas for increasing speed and productivity by reducing the dependence on human power in production activities as well to ensure continuity of production. Offering various options appropriate for the desires and needs of producing firms, our company is always with them as a solution partner.

Join us in revolutionizing the PVC production industry with our advanced PVC dosing, feeding, and mixing systems. Since 2004, ChiYu Company has been a leading manufacturer of top-quality PVC equipment and accessories, earning an outstanding reputation worldwide. Our dosing systems offer maximum capacity, efficiency, and consistency by precisely weighing formulations and transferring them into feeding silos. Plus, our other innovative equipment such as the big bag weighing unit, screw conveyors, flexible spiral conveyor, pneumatic conveying system, raw materials storage silo, liquid dosage unit, hopper, and automatic feeding system can further streamline your production process. Let's work together to save time, reduce waste, increase productivity, and achieve unparalleled results. Contact us today to learn more!