Horizontal ribbon mixer is a low speed mixer, therefore no heat generated during mixing, so it also becomes a horizontal cooler mixer. Suitable for power or pellets mixing especially heat sensitive chemicals mixing. It provides a very good distribution and mixing than other type low speed mixers. chiyu as a professional horizontal ribbon mixer manufacturer, we provide design, development and production of horizontal ribbon mixer. Contact us for one-on-one guidance!

Horizontal ribbon mixer is widely used in chemical, pharmaceuticals, food, and construction line. It can be used to mix powder with powder, powder with liquid, and powder with granule.Under the driven of motor, the double ribbon agitator mix the material quickly. This horizontal ribbon mixer is characterized by high mixing effect, large productivity, and a very low failure rate. Since it is a batch type mixer, customer should choose the model according to the output per batch.

Technical parameter:

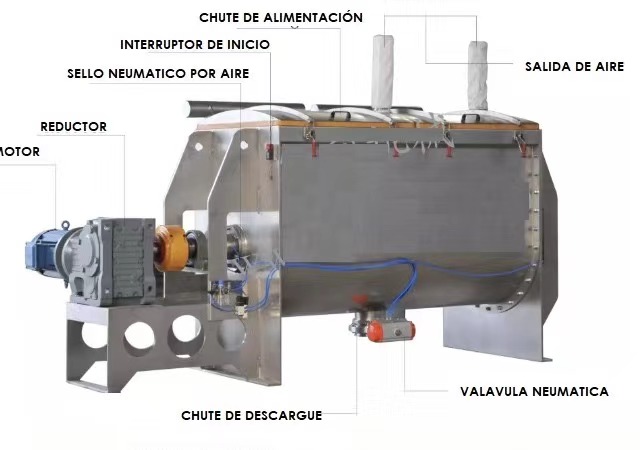

Mixer tank: horizontal, U-shaped tank

Shaft: horizontal, hollow, integral single shaft

Batch working volume: 0.1-15cbm

Mixing time: 15-60mins

power: 3kw-160kw Material: 316L, 304, mild steel

Selection way:

1. Choose the batch working capacity from 0.1cbm to 20cbm, select mixer accordingly.

2. Choose material for the part contact with raw material, non-contact with raw material, other parts like motor and reducer, bearing material can not be chosen; According to the material to be mixed, processing condition, health level, raw material can be mild steel, sus304, sus316L, sus321; And choose the surface treatment according to the raw material.

3. Motor power is chosen according to the material gravity, fluidity, and operation.

Operation is divided as: Start mixer when it is empty (normal duty); Start mixer with load (heavy duty)

4. Adding the auxiliary components like spraying, heating and cooling according to processing condition.

5. Mixer inlets: feeding ports, cleaning port, vent.

6. Chose discharging and driven mode: manual, pneumatic and electric.

Note: mixer selection is a very important step, your detailed material information, processing and factory arrangement are very helpful to get professional technical support from us.

chiyu as a professional horizontal ribbon mixer manufacturer, we provide horizontal ribbon mixer design, development and production. If you want to get detailed information about the horizontal ribbon mixer price, you can click here to contact us!