Powder dilute phase pneumatic conveying systems is essentially a process that transfers material with low pressure and at high velocity. Lean Phase pneumatic conveying system is a suitable process for conveying of non-friable and non-abrasive materials suspended in air with low material to air ratio.

Powder Dilute Phase Pneumatic Conveying Systems Bulk Bag Loading Systems

Powder dilute phase pneumatic conveying systems is essentially a process that transfers material with low pressure and at high velocity. Lean Phase pneumatic conveying system is a suitable process for conveying of non-friable and non-abrasive materials suspended in air with low material to air ratio.

Also referred as suspension flow, most of the materials are conveyed irrespective of the particle size, shape or density.

Powders with low bulk density that are fine in nature with less air retention capability are conveyed in suspension flow in a dilute mode wherein material to air ratio is low.

Our customized solutions are suited to meet the various process needs as well as different industrial applications. With an experience of over 20 years, we are one of the leading Dilute/ Lean Phase conveying systems manufacturers.

Types of Lean Phase conveying system

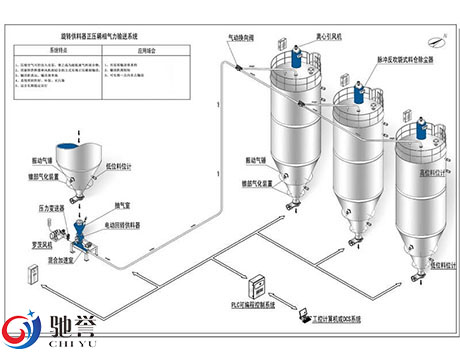

1. Positive Pressure type:

Positive pressure systems operate above atmospheric pressure and are used to convey bulk materials over medium distances with greater capacity than using vacuum systems

With diverter valves, multiple destination delivery one after the other reception points can be arranged easily with positive pressure systems.

Multiple feed points into a common line can also be provided ensuring proper selection and air quantity and special conveying Rotary air lock valves.

Basic parameters

1.Minimal material degradation as the material is transported at low velocity.

2.Handles wide variety of material such as fragile, abrasive and friable as well as materials with high bulk densities.

3.Minimum wear and tear of the system.

4.Minimum Maintenance.

5.No material spillage, no dust emission, clean environment.

6.Low Noise operation.

7.Low air flow rate.